|

|

||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

|

Moonlight Mint’s Grabener Coin Press - Facts, Figures, History, and Artifacts. Compiled by Daniel Carr |

||||||||||||||||||||||||||||

|

Grabener coin press number GK MP 360 / 31824 was manufactured in Germany in 1986. It went directly into service at the US Denver Mint, where it was employed to strike all of the mint set coins, commemorative coins, and medals produced at the Denver Mint from 1986 to approximately 2001. When the Denver Mint ceased production of commemorative coins in the late 1990s, the press became surplus. It was sold at auction in 2001, and then sat disassembled and collected dust for six years in a warehouse outside Denver. Moonlight Mint acquired it in early 2007 and completed the restoration in December 2008. This page documents the highlights of that project.

The press as it appears currently:

Denver Mint Grabener Press identification plates. Maximum stamping force of 360 metric tons (403 US tons):

The following pictures show the press prior to restoration.

During the restoration process (which was performed by Daniel Carr), many interesting artifacts were discovered inside it. These artifacts include over 400 un-struck coin blanks (cents, nickels, dimes, quarters, and half dollars), several normally-struck coins and medals, and other debris.

The oil pan at front of machine yielded several normally-struck coins and medals:

The oil pan on left side of press below flywheel contained a few blank planchets:

The oil pan on right side of press near oil pump contained several blank planchets:

The rear of the press, where the electric motor is located, contained many blank planchets. The dirt and grime buildup from years of use and storage are evident. This area, along with all other parts, have since been completely cleaned up:

The base under the conveyor motor was the hiding place for a large quantity of blank planchets. One can be seen peeking out in this photo:

Many more blank planchets were found under the mounting plate behind coining chamber. A couple can be seen here next to their hiding place:

Automatic feeding system with two blue rejection bins for coin blanks that are underweight, overweight, too big, too small, bent, etc.:

You don’t suppose there were still some blanks left in those bins ? Yes ! It is surprising that so many blanks were just left there, and that they remained undisturbed for several years while the press sat in a busy warehouse:

Do you ever wonder what happens to the split (lost) clad layers from some US error coins ? Well, in a few cases, they ended up inside the conveyor (feeder) mechanism. Shown here (from front to back): two copper cores from dimes; two crumpled outer clad layers from quarters, clad blank webbing from quarter and dime stock; damaged quarter and dime blanks:

Table top covered by oily coin blanks, struck coins, medals, and other debris removed from press:

Closer view of some struck coins and struck medals. Note the small cent-sized “D” medals that go into packaged mint sets. The large piece is a John Adams president medal with a “D” mint mark:

The main adjuster bolt for the lower block was broken. A replacement bolt from Germany was $880, and I had to modify it to make it fit:

Turntable (indexer) with stainless-steel feeding fingers for quarters:

Large wooden crate with spare parts and misc:

A couple hundred feeding fingers were in the crate. But two in particular are interesting. Why the red “X” ??? :

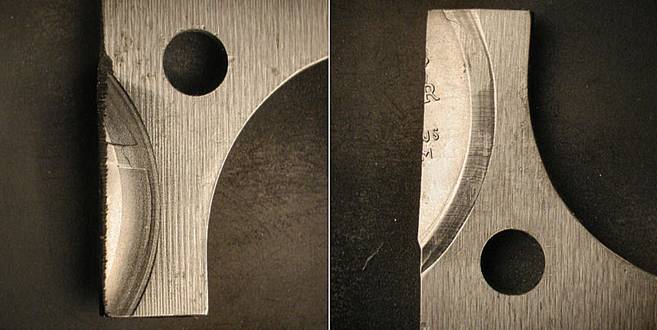

Yes, on the left is a complete stainless steel finding finger for silver dollars, which was hit by dies for the 1992-D White House commemorative silver dollar. And on the right is another one that got hit by dies for the 1992-D Columbus commemorative silver dollar:

Close-up photo of 1992-D White House silver dollar feeding finger:

Close-up of 1992-D Columbus silver dollar feeding finger:

Another Columbus silver dollar feeding finger, partially effaced. However, the “1492” date is incuse on the coin, and so it can still be seen on the feeding finger:

Two more silver dollar feeding fingers that were clipped by unknown dies:

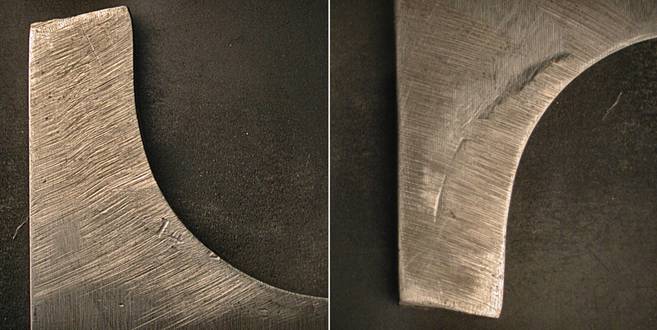

This silver dollar die was effaced by the US Mint. Used dies such as this are supposed to be TOTALLY effaced. I was preparing this die for re-engraving for my own use, but after heat-treating (annealing), it was evident that some of the original design detail remained. After careful study, it is now apparent that this die was used for the reverse of the 1993-D World War 2 commemorative silver dollar. Much of the word “UNITED” remains, as does a quotation mark and part of a small “w”. The picture on the left has been mirrored for easier visual comparison. After annealing, it was also obvious that this die has a serious crack (visible on right picture running from die face towards serial number). Small punch mark in center of die face is from recent hardness test. Since this Grabener press is believed to be the only one to strike silver dollars at the Denver Mint from 1986-2001, this die was most likely used with this particular press:

I almost threw this piece of wood away until I looked at the other side. It is the lid for a secure shipping crate for dies and hubs to be sent from the Philadelphia Mint to the Denver Mint:

Wax seals with Philadelphia Mint logo impressions cover the screw heads that held the lid on:

Most of the blank planchets, struck coins and medals, and other debris from inside the press can be seen in this picture (after oil removal and clean-up):

Oops. The US Mint lost track of this reeded-edge quarter-dollar collar and sold it with the coin press. Laser-engraved US Mint serial/tracking number is C-103-7-X #27463-039 . This collar was used when minting the Grabener Coin Press “25” medals (see next picture after this image of the collar):

One of the first projects for the press after restoration was to strike commemorative medals on the coin blanks (and other debris) found inside the press. So here you have medals commemorating the press’s service at the Denver Mint, and they were struck by the press being commemorated, on blanks that were found inside it. These press medals will ONLY be struck on the blanks found inside the press (and on other debris found inside such as a few washers, and key heads). Shown here is the “25” medal struck on a copper-nickel clad quarter-dollar blank. Click this link for a complete list of specifications and mintages. Conceived, designed, sculpted, engraved, and struck by Daniel Carr.

All the medals produced at the Denver Mint from 1986-2001 were made on this Grabener press. As such, this 38mm Denver Mint medal struck off-center is one of the few mint error pieces traceable to this particular machine:

Another such error coin, and perhaps the most valuable item ever produced by the US Mint using this Grabener press, is the 1989-D Congress commemorative silver dollar with the reverse rotated 180-degrees from normal. It is estimated that about 200 of these were struck in error with “medal-turn” alignment before the problem was corrected and the rest were stuck using the normal “coin-turn” orientation. Current market values for these coins, which are rarely available, is around $1,500-$2,000:

The following are more pictures of the coin press and workshop as it appears currently.

65 horsepower electric motor runs flywheel:

Large transformer steps-up input voltage from 208 volts (3-phase) to 480 volts (3-phase):

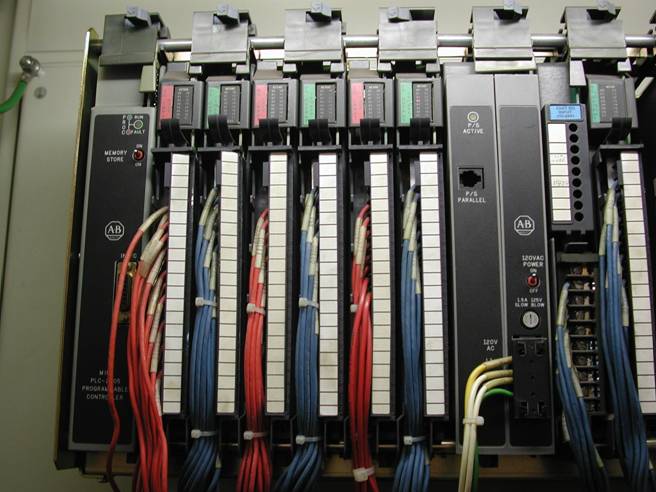

Electrical cabinet contains 1986 vintage Allen Bradley industrial controls. A lot of time was spent working in this cabinet, fixing faulty relays, tracking down loose connections, fixing incorrect wiring, and replacing a dead PLC power supply. Note the three huge 200-Amp fuses on the input line at upper right. A few coin blanks were also found in here:

Power supply (on right) was dead. It supplied power to the PLC (Programmable Logic Controller, on left). A new power supply unit cured the problem:

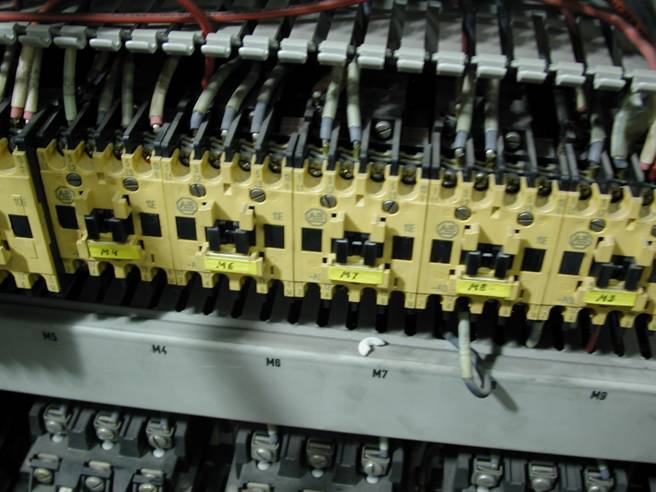

A piece of a white plastic grommet (seen here above the “M7” label) was lodged in one of the relays, preventing it from operating properly:

Multi-pin cable connector on side of electrical cabinet. Multiple wires run inside black cable and connect to various pins on the inside of cable head. Inexplicably, one pin had a wire that connected to nothing on the other end. And one other wire that ran to a sensor on the indexer (turntable) did not connect to any pin inside the head. This caused a chronic “Indexer Fault” problem. Swapping the wires inside the head cured the problem:

The coin press originally had a heavy sound enclosure around it, but was long gone. The press is not loud (unless a whole bucket of coin blanks is dumped into the hopper). But the accumulated noise from 20 of these presses running on a shop floor would require noise abatement. The brains of the coin press had been programmed in such a way that it would not function in normal mode if any one of the sound enclosure doors were open. After considerable sleuthing, it was determined that a multi-pin electrical cable ran from the top of this junction box on the top of the coin press, to a similar box mounted on the inside of the sound enclosure. After several tries, the exact pin-jumping arrangement was found. The three black wires fool the PLC into thinking that all the sound enclosure doors are shut. Only this exact configuration of jumper wires will allow the press to function:

Giant flywheel is partially visible on left side. Auction lot sign with lot number “2624” is 2001 vintage:

Among the disarray of documents that came with the coin press were these 8.5” x 11” prints of the first five (1999) state quarters. Apparently, they were taped on the front of the press during setup and operation so that the operator could have something to compare the struck coins to. Three normally-struck state quarters were found inside the coin press (DE, NJ, and CT):

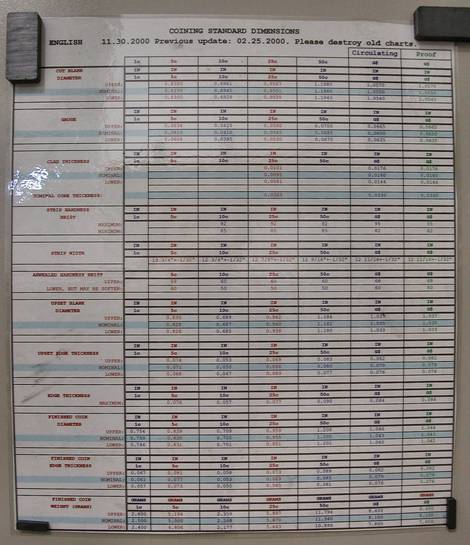

Another document shows detailed specifications (diameter, weight, etc.) for circulating coin blanks and finished coins. Hmmm… :

A different kind of “Rec Room”:

In action (blurred part of press super-structure is in motion):

2009 Amero just struck:

Colorado Springs thrift-shop find (lunch bag) seems appropriate:

|

||||||||||||||||||||||||||||